-

Your shopping cart is empty!

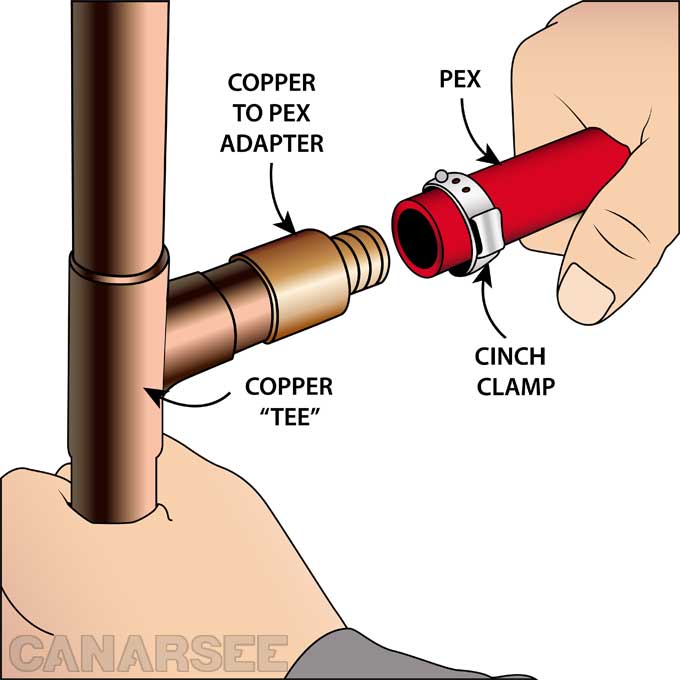

With the annual increase of PEX tubing utilization in domestic plumbing systems consumers are constantly retrofitting their piping systems. Most piping systems are originally constructed of Copper, CPVC, or PB piping. The need for retrofitting has grown rapidly in recent years due to older less efficient systems faltering. Most homeowners don’t see the need in re-piping whole systems due to minor expansions or a faulty pipe. When this is the case, the best possible variant is using an adapter to connect two different types of piping to co-exist within the same system. One such adapter connects Copper piping to PEX tubing, allowing the consumer to either add an existing line or replace a faltered one with ease.

There are two different methods to connecting copper pipe to PEX tubing: Crimp/Clamp Connections and Push-Fit/Speed-Fit Connections

The more conventional connection method used with PEX tubing is the crimp/clamp method. This connection method utilizes a 360 degree compression of a crimp/clamp ring around the PEX tubing’s outside diameter to ensure a proper connection is made. The connection can then be checked with a Go-No-Go-Gauge to ensure a proper connection is made.

*Note* Solder Copper components first to ensure the PEX tubing is not damaged by the fire.

Step 1: You will need to solder the Copper end of the adapter together with the copper pipe using solder flux in the process.

Step 2: Once the Soldering Process is complete, slide the clamp/crimp ring of appropriate size onto the PEX tubing. Place the PEX tubing with the attached ring over the adapter.

Step 3: Use the necessary tool required to make your connection such as a Crimp or Clamp tool. Make sure that the ring is positioned over the middle of the adapter for a tight and secure connection.

PEX Installation: Clamp Style Connections & Declamping

PEX Installation: Crimp Style Connections & Decrimping

The easier of the two methods is the Push-Fit connection which requires no tools to perform the task. Utilizing an O-ring seal these fitting connect the two pipes by latching onto their outside diameters. It is important that the fitting being utilized complies with the outside diameter rating for the two different pipes.

*Note* Copper and PEX tubing of the same size such as ½" do not contain identical Outside Diameters. Step 1: If the Push-Fit/Speed-Fit fitting is not sold with a pre-installed sleeve then insert a sleeve into the PEX Tubing. This step will aid in equipping a tougher interior and prevent the PEX from breaking the seal and collapsing.

Step 2: Place the properly cut PEX Tubing within the seal until a click is heard or you can feel that the O-ring has properly tightened around the tubing.

Step 3: Properly installing the Copper Pipe end of the fitting requires no sleeve due to coppers rigid toughness. Check that the Copper Pipe has a clean cut, and place it within the fitting until a click is heard. If there is no click heard just double check that both sides of the connection are tight and secure.

*No Tools Necessary*